Introduction to Waterproof Sealing Ring

Introduction to Waterproof Sealing Ring

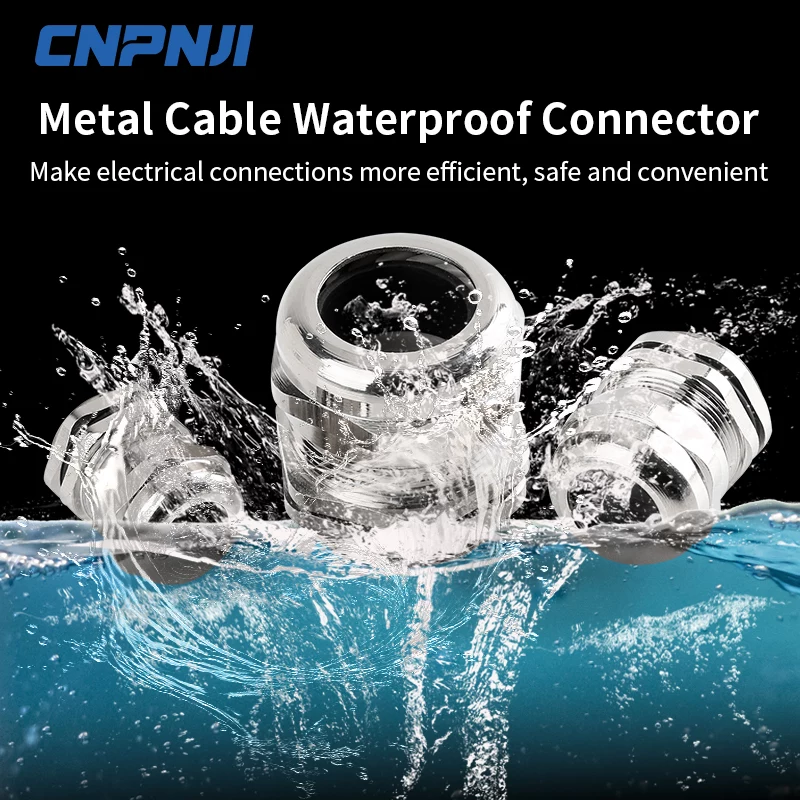

The waterproof sealing ring of metal waterproof joint is a key component used to ensure the waterproof performance of the joint in various environments. Here is a detailed introduction to it:

1. Material

Waterproof sealing rings are usually made of high-quality elastic materials, mainly including:

Silicone: resistant to high and low temperatures, with good elasticity, suitable for a wide range of industrial applications.

Nitrile rubber (NBR): excellent oil resistance, suitable for oil and gas pipelines and electrical equipment.

Viton: High temperature resistant, corrosion-resistant, suitable for harsh environments.

EPDM: It has good weather resistance and UV resistance, and is commonly used in outdoor applications.

2. Function

Sealed waterproof: prevents moisture or dampness from seeping into the interior of the equipment through the joint.

Anti vibration: Provides a certain buffering and vibration absorption effect to protect the joint and its internal components.

Enhance connection stability: The sealing ring fits tightly with the metal joint to ensure the stability of the overall structure.

3. Structural characteristics

O-ring: The most common sealing ring structure, simple and effective, widely used for static and dynamic sealing.

Cone sealing ring: suitable for waterproof requirements under specific pressure, providing better sealing effect.

Multi layer sealing ring: provides multiple sealing barriers in high protection level (such as IP68) applications.

4. Scope of application

Industrial equipment: such as motors, electrical control boxes, waterproof switches, etc.

Outdoor facilities: such as street lamps, signal equipment, and communication equipment.

Ship and Ocean Engineering: Provides excellent waterproof performance to cope with humid, salt spray and other environments.

Automobiles and rail transit: Ensure the reliability of wiring terminals and connectors in harsh environments.

5. Precautions for selection

Size: Ensure that the size of the sealing ring matches the metal joint.

Environmental adaptability: Choose suitable materials based on the usage environment, such as high temperature resistance, chemical corrosion resistance, etc.

Protection level requirements: The sealing ring should meet the required protection level of the equipment (such as IP65, IP67, or IP68).

6. Maintenance and replacement

Regular inspection: prevent seal failure caused by aging or wear.

Timely replacement: Ensure the long-term waterproof performance of the equipment.

Installation precautions: Avoid damaging the sealing ring during installation.

By selecting and using waterproof sealing rings reasonably, metal waterproof joints can provide excellent sealing performance and reliability in various harsh environments.