Glue injection of the junction box

Glue injection of the junction box

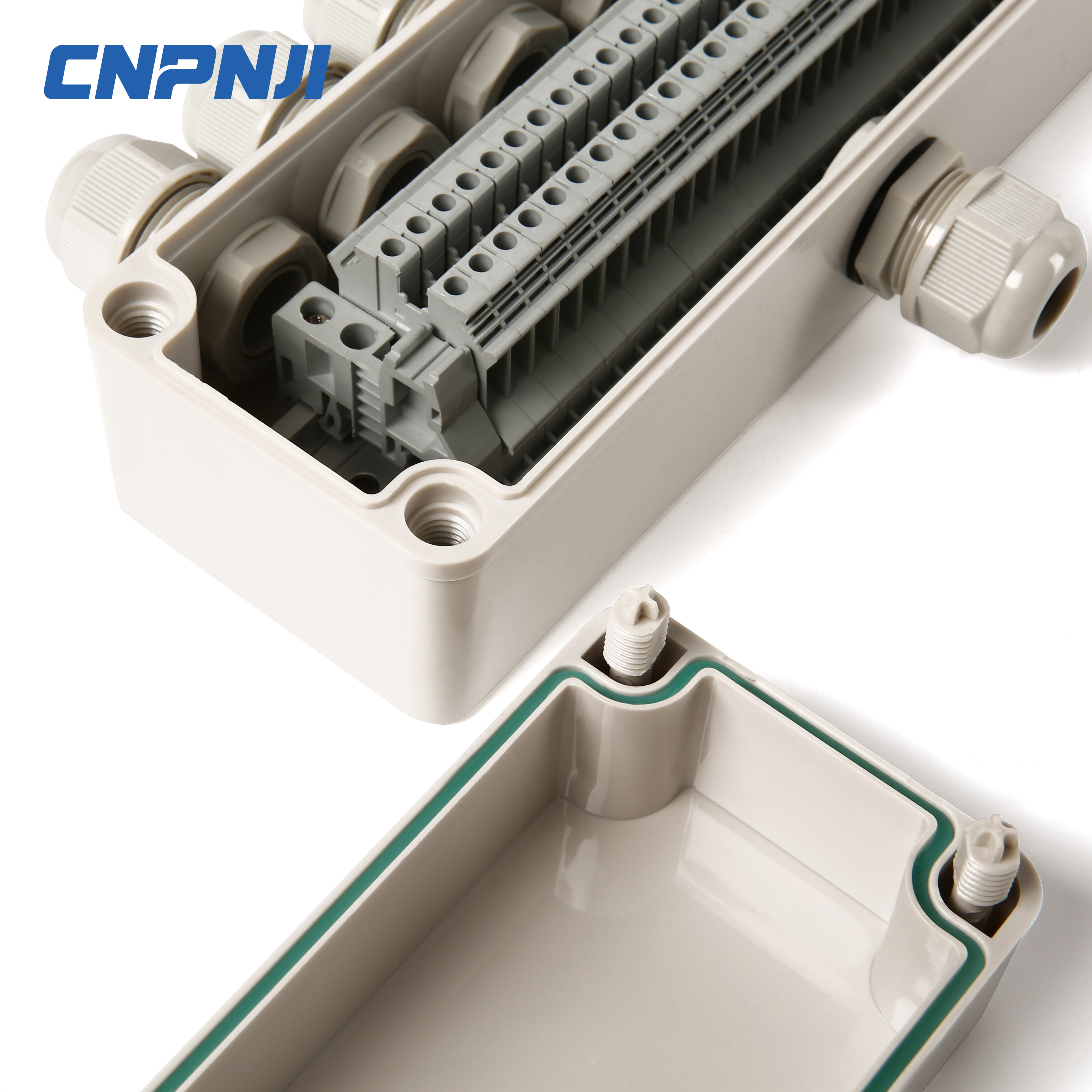

The glue injection of the junction box is to inject liquid silicon gel into the inner gap of the junction box cover, so that after tightening the bolts at four corners, the bottom shell of the junction box and the box cover can be tightly connected to achieve the purpose of waterproof. In the production process, the inner gap of the waterproof box should be cleaned first to ensure that there is no plastic burr or other impurities. Then put the ABS plastic box on a flat workbench without any other sundry, start the automatic dispensing machine, and the automatic dispensing machine will completely inject liquid silicon into the ABS plastic box along the inner surrounding gap. During the use of the dispensing machine, it is necessary to observe whether the total amount of glue dispensing into the enclosure is consistent, whether the glue is uniform, whether the liquid level and air pressure are stable, etc. Press the emergency stop button immediately in case of emergence. After gluing the cable junction box, the gluing machine should be cleaned in time and the power supply should be turned off. The inner gap of the waterproof box are evenly filled with black liquid silicon gel, which becomes the key part of the waterproof box after solidification, ensuring the enclosure is waterproof.