Diagram of wire connection about single strand copper

Wire connection is a basic procedure in electrical work, and its connection quality is directly related to the long-term safe and reliable operation of the whole line. The basic requirements of wire connection are: firm and reliable connection, small joint resistance, corrosion resistance and oxidation resistance, good electrical insulation performance and high mechanical strength. According to the type of wire and the different form of connection, common connection methods can be divided into the following: stranded connection, compression connection and welding. Before connection, the insulation layer at the connection part of the conductor shall be removed carefully, and the core wire shall not be damaged. Copper wires are often connected in a stranded manner.

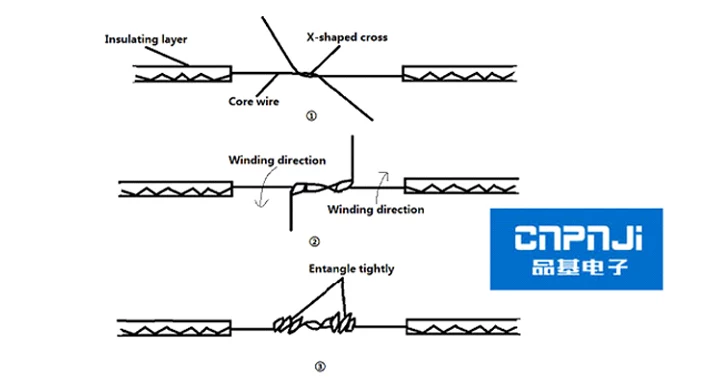

(1) The connection method of small section single strand copper wire is shown in the figure below. First, make X-shaped intersection between the core wire ends of the two wires, then wrap them around each other for 2-3 turns before straighten the two wire ends. Finally, tightly wrap each wire on the other core wire for 5-6 turns and cut off the excess wires.

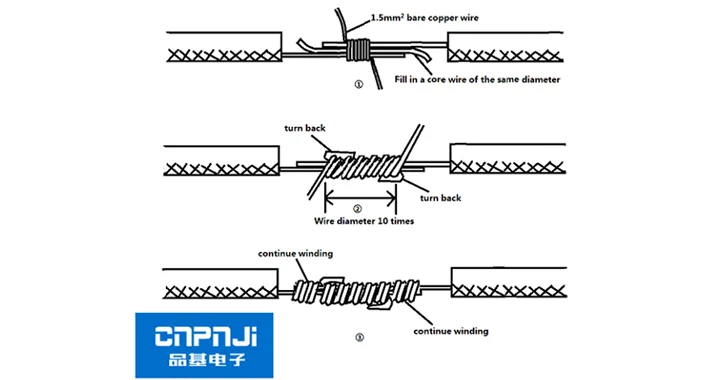

(2)The connection method of large section single strand copper conductor is shown in the figure below. First, fill in a core wire of the same diameter at the overlap of the two wires, and then use a bare copper wire with a section of about 1.5mm2 to tightly wound on it. The winding length is about 10 times of the diameter of the conductor. Finally, turn back the core wire ends that we need to connect and continue winding the bare copper wire for 5-6 turns, then cut off the excess wire.

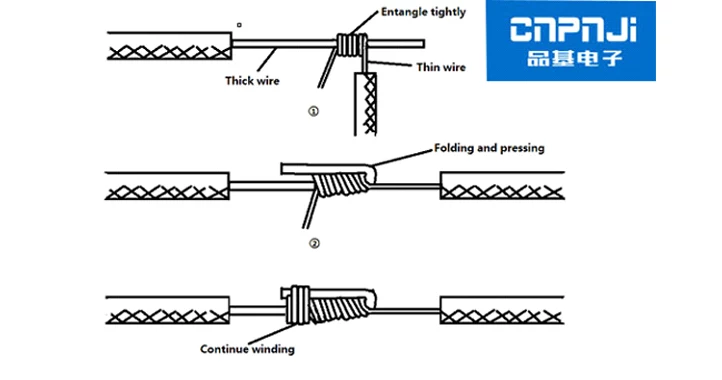

(3)The connection methods of single copper wires with different sections are shown in the figure below. First, wrap the core of the thin wire around the core of the thick wire for 5-6 turns, then fold the core of the thick wire back and press it tightly on the winding layer. Finally, wrap the core of the thin wire around it for 3-4 turns and cut off the excess wire.